Ok, so I was playing hookie from work and I got bored. I had an idea...I was looking at the brake/rudder pedal assemblies and I saw those little round circles on the end of the 7/8" tubing. What apain, I thought, to make those. So, I got to looking at the holesaw and arbor I got from Home Depot. I think Sandvic makes them...but anyway...

The drill bit in the arbor is 1/4", too big for the brake pivot shaftdiameter of 3/16". So, I dug through my scrap steel box and pulled out some 5/16" solid steel bar...some cheap stuff I think I picked up at Tractor Supply awhile back. I chucked it in the lathe and drilled the centerout 11/64". I turned the outside down to .250.

I then cut off the piece at .750 length and inserted the drill shank into the adapter I just made. I filed a groove for the arbor set screw like so:

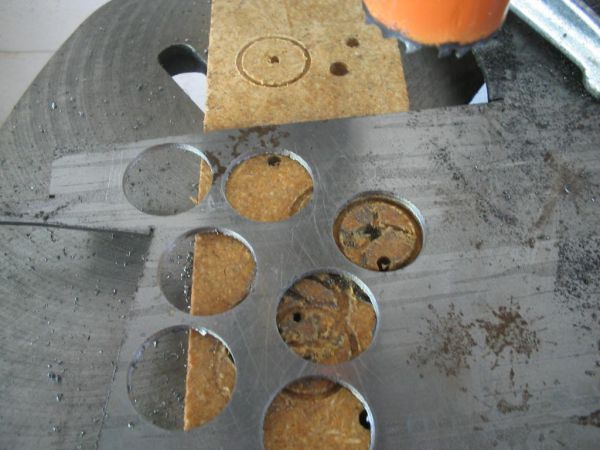

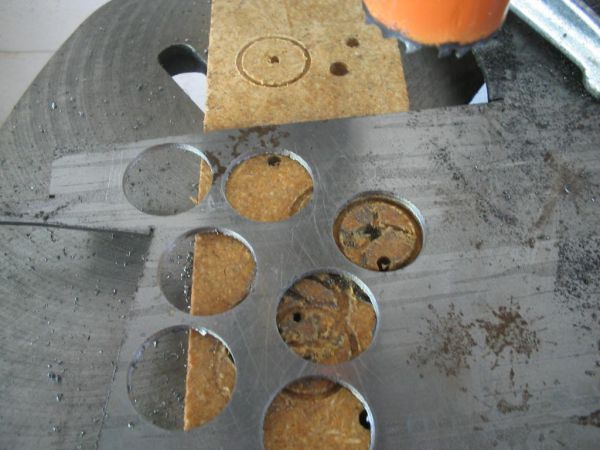

Insert into holesaw arbor and procede to cut 8 circles with perfectly centered holes out of .100 4130 sheet. Your 11/64 hole is then ready to be reamed out to 3/16" for the pivot axles.

Make sure you put the sheet on top of some wood. I used 300rpm setting on my drill press and kept lots of lube/coolant on the holesaw. It did all eight without damaging any teeth.

You'll have to dress the edges with your belt sander or file.

Then I got to the task of cutting the rest of the pieces I'll need for the pedals.

The rectangle pieces will form a circular shape around the 7/8" tube at the top of the rudder pedal, where it is welded to the verticle 7/8" tube that holds the brake pedal shaft.

I'll round it off once I get sone 7/8" tubing to match it up with.

Next was the brake master cylinder brackets. Cut to shape/length and welded around the perimieter to 3/4" from the end. I clamped the drilled end together with a bolt, and clamped the other end to some 1/2" steel bar fromt he scrap box. Finished product waiting to be welded on to the brake pedal:

I cut some1/2" .035 tubing I had laying around. I tack-weldedtwo corners. the bottom piece I left loose because I have to notch the center piece. More to come later....here is what I fitted up:

Enough for now....I'm tired. I have to order me some 7/8" tubing and get some sleep.

The drill bit in the arbor is 1/4", too big for the brake pivot shaftdiameter of 3/16". So, I dug through my scrap steel box and pulled out some 5/16" solid steel bar...some cheap stuff I think I picked up at Tractor Supply awhile back. I chucked it in the lathe and drilled the centerout 11/64". I turned the outside down to .250.

I then cut off the piece at .750 length and inserted the drill shank into the adapter I just made. I filed a groove for the arbor set screw like so:

Insert into holesaw arbor and procede to cut 8 circles with perfectly centered holes out of .100 4130 sheet. Your 11/64 hole is then ready to be reamed out to 3/16" for the pivot axles.

Make sure you put the sheet on top of some wood. I used 300rpm setting on my drill press and kept lots of lube/coolant on the holesaw. It did all eight without damaging any teeth.

You'll have to dress the edges with your belt sander or file.

Then I got to the task of cutting the rest of the pieces I'll need for the pedals.

The rectangle pieces will form a circular shape around the 7/8" tube at the top of the rudder pedal, where it is welded to the verticle 7/8" tube that holds the brake pedal shaft.

I'll round it off once I get sone 7/8" tubing to match it up with.

Next was the brake master cylinder brackets. Cut to shape/length and welded around the perimieter to 3/4" from the end. I clamped the drilled end together with a bolt, and clamped the other end to some 1/2" steel bar fromt he scrap box. Finished product waiting to be welded on to the brake pedal:

I cut some1/2" .035 tubing I had laying around. I tack-weldedtwo corners. the bottom piece I left loose because I have to notch the center piece. More to come later....here is what I fitted up:

Enough for now....I'm tired. I have to order me some 7/8" tubing and get some sleep.