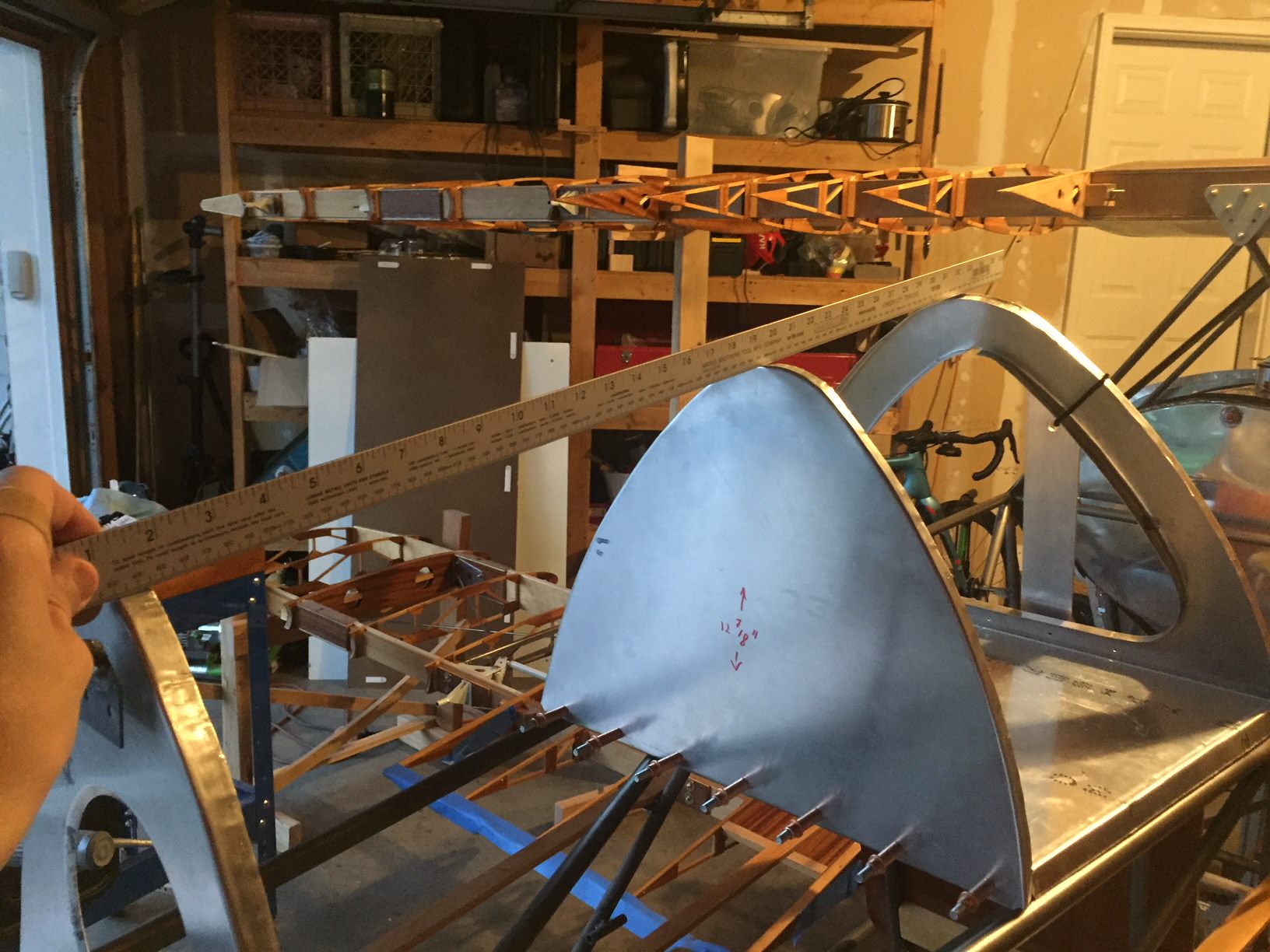

I'm having a hard time getting everything to stay in place and clamp flat so that I can start drilling and cleco-ing a skin to my turtle deck. It feels like 8 pairs of hands wouldn't be enough. Is there a trick to this? I've got three bulkheads and a seat pan that make a straight line:

a skin that hasn't been trimmed to length, but has been cut for the H-stab tube, vertical stabilizer, and trimmed to width:

a few failed attempts to get everything to lay flat:

I also have extra aluminum, if I'm on the wrong track altogether. I made a template for this skin out of card stock, but that is much easier to work with.

Unfortunately what I don't have is the experience with sheet metal to know where I'm going wrong. Any tips?

I suspect that the right way is to abandon the cardboard template, drill and cleco along the "spine" of the t-deck with a skin that only has the v-stab cutout, and then gradually work towards the edge, drilling and cleco-ing as I go. I'm a little concerned about twisted bulkheads if I do that though, as I'll still need to hold three things in fixed places while I drill.

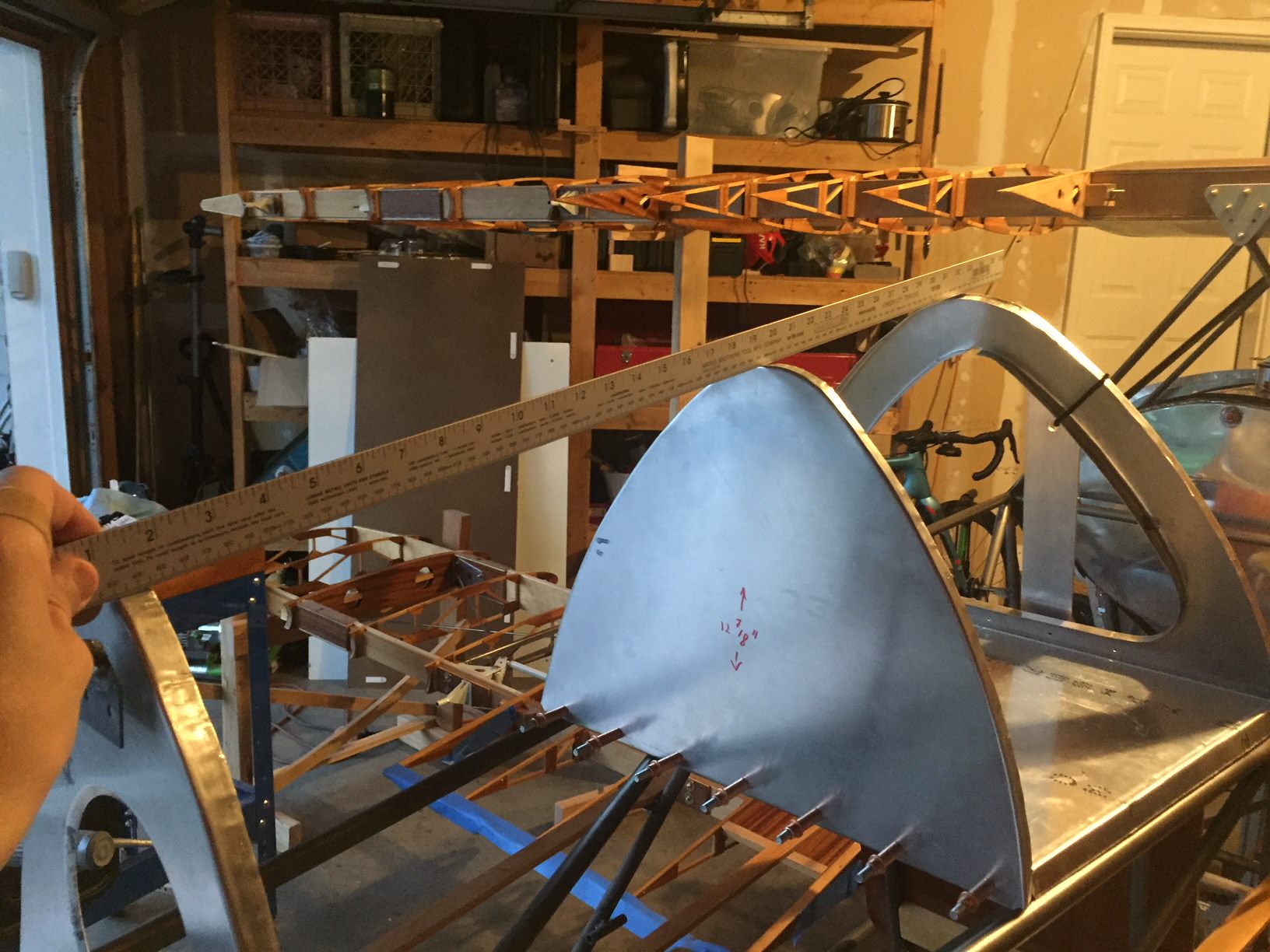

a skin that hasn't been trimmed to length, but has been cut for the H-stab tube, vertical stabilizer, and trimmed to width:

a few failed attempts to get everything to lay flat:

I also have extra aluminum, if I'm on the wrong track altogether. I made a template for this skin out of card stock, but that is much easier to work with.

Unfortunately what I don't have is the experience with sheet metal to know where I'm going wrong. Any tips?

I suspect that the right way is to abandon the cardboard template, drill and cleco along the "spine" of the t-deck with a skin that only has the v-stab cutout, and then gradually work towards the edge, drilling and cleco-ing as I go. I'm a little concerned about twisted bulkheads if I do that though, as I'll still need to hold three things in fixed places while I drill.